About Us

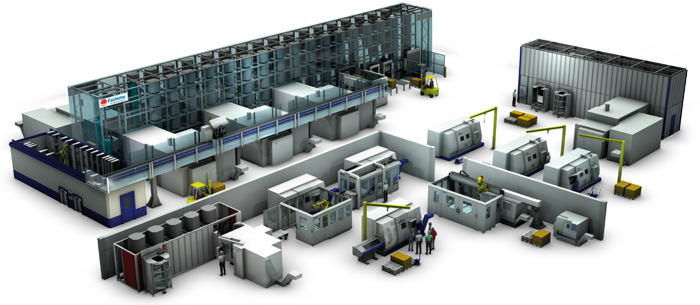

PARC TECH has a proven experience in providing design and detail engineering, manufacturing across multiple disciplines and industries. This includes water treatment, power, fertilizer, cryogenics, pharmaceuticals, metals, and minerals, onshore oil and gas refineries / plants, petrochemicals, as well as off-shore fixed well-head type platforms and floating production, storage, and offloading (FPSO) vessels.

Our services include design and detail engineering, pre-bid engineering support, procurement support, construction support (related to detail engineering),

manufacturing and as-built engineering. Parc Tech offers a complete multi-disciplinary engineering solution utilizing advanced

software for FEM analysis, design, detailing, plant 3D modeling, and drafting.

We are a Singapore-leading product service provider and exporter of Carbon steel, stainless steel coil, sheet, pipe, flanges, fittings, bar, and passed the SGS TUV Certification of Singapore Supplier System, Parc Technologies is committed to provide professional service to global clients including the lowest price support, professional technical support, flexible payment methods, strong financial support, has become the most reliable partner in the carbon steel and stainless steel industries.

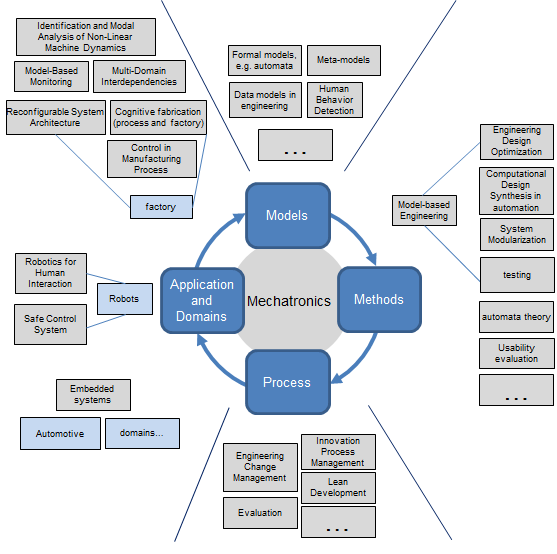

Process Engineering

Typical detail engineering documents and tasks include:

- Preparation of design basis

- Preparation of project specification

- Procees Design and Simulation

- HAZOP Studies

- Development of PFD, UFD and P&ID

- Preparation of Cause & Effect Diagrams (CED)

- Basic & Detailed Engineering Design

- Process & Equipment Data sheets

- Preparation of Line List

- Preparation of Equipment List

- Our engineer shave expertise in related activities such as review of design criteria,review of contractor design documents and drawings and project coordination.

- Team is experienced in the use of a variety of supporting software including Hysys, HTRI and Pipe NetMicrostation.

Typical detail engineering documents and tasks include::

- Structural Analysis

- Structural Drawings for Platforms, Handrails, Walkways, Ladders, Weld Details etc.

- Weight Control Report

- Skid Lifting Arrangements

- Structural Modelling

- Transportation Analysis

Civil Engineering

- Preparation of design basis

- Pile and conventional foundations

- Cable and pipe trenches and tunnels

- Pipe and cable rack structures, conveyor galleries, trestles, stack supporting structures, and platforms

- Preparation of project specification

- Equipment and machinery foundations

- Roads, pavement, grading plans, and drainage systems

- Large diameter/size storage sheds

- Reinforced concrete framed structures

- Concrete storage silos and large diameter storage tank foundations

- Steel framed buildings and superstructures

- Our engineers have expertise in related activities such as review of design criteria,review of contractor design documents and drawings,and project coordination.

- Team is experienced in use of various software including PDMS,STAAD Pro,AutoCAD and TEKLA Structures(Xsteel)

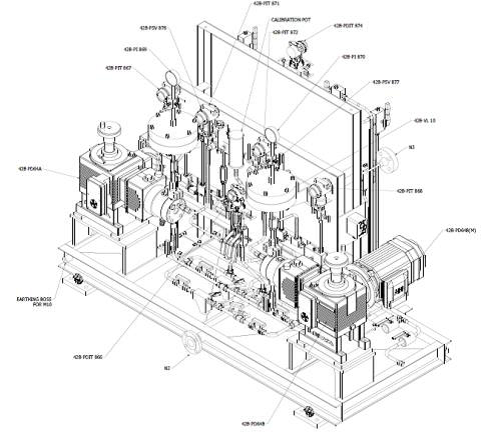

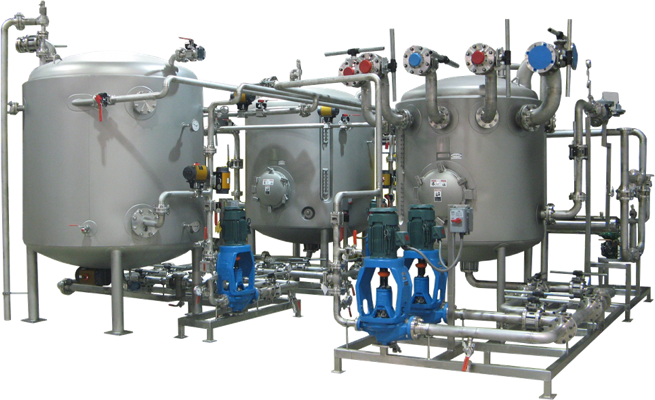

We delivers design and detail engineering of static and rotating equipment, packages. We have worked with static equipment including pressure vessels, shell and tube heat exchangers, storage tanks, towers, reactors, condensers, and evaporators.

- Mechanical data sheet preparation

- Strength calculations

- Preparation of general arrangement drawings

- Detailed Fabrication drawings

- Preparation of bill of materials

HVAC Engineering

- Heat load calculations

- Design/ selection of equipment

- Pressure loss calculations

- General arrangement drawings

- Duct Layout drawings and cross sections

- Duct support drawings

- Material take off

- Design of ducts according to SMACNA, DW standards

- Our engineers have expertise in related activities such as review of design analysis, review of contractor design documents and drawings, and project coordination.

- Our team is familiar with various international codes and standards like ASME Section VIII Div-1and Div-2 and API 650

- Team is experienced in use of various software including PVElite and AutoCAD

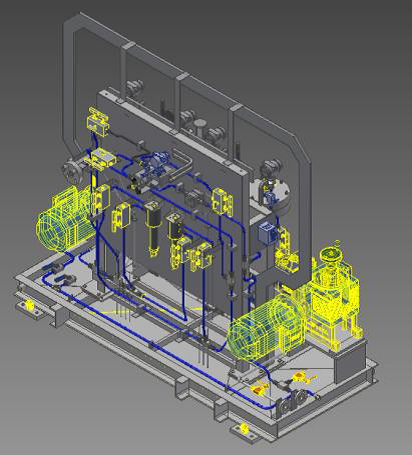

- Piping material specifications

- 3D model project set-up

- Painting and insulation specification

- Site survey / tie-in sketches

- Updating plot plans and unit plot plans

- Equipment modeling

- Nozzle orientation drawings

- Modeling of lines

- Interface with other disciplines

- Stress analysis

- Pipe supports

- Clash checking

- Model reviews

- Piping general arrangement drawings

- Isometrics

- Piping material take-offs

- Support material take-off

- Insulation and painting take-off

- Tracing / jacketing

- Our engineers have expertise in related activities such as review of design criteria, review of contractor design documents and drawings, and project coordination

- Team is experienced in the use of a variety of supporting software including Smart Plant 3D, PDS, PDMS, CADWorX, AutoPLANT 3D, Inventor, Solidworks,BIM, AutoCAD, Microstation, Smart Plant Review, Navisworks, CAESAR II and MDS – Support Modeler

- Preparation of design basis

- Preparation of project specification

- Single Line Diagram

- Electrical Load List

- Cable tray / trench layouts

- Earthing layouts

- Cable routing layouts

- Lighting (indoor/outdoor) layouts

- Lightning protection layouts

- Lighting Wiring Diagram

- Power and control cable schedules

- Bill of quantities for bulk materials

- Our engineers have expertise in related activities such as review of design criteria, review of contractor design documents and drawings and project coordination.

- Team is experienced in the use of a variety of supporting software including ETAP, Smart Plant Electrical,BIM, AutoCAD and and Microstation.

- Preparation of design basis

- Preparation of project specification

- Preparation of control philosophy

- Preparation of detailed execution drawings

- Preparation of instrument index

- Preparation of instrument elevation plan

- Preparation of interlock logic diagrams

- Preparation of cable tray / cable trench layouts

- Preparation of junction box termination drawings

- Preparation of instrument hook up drawings

- Preparation of cable schedules

- Preparation of fire and gas drawings

- Preparation of cause and effect drawings

- Technical bid evaluation

- Review of vendor package systems

- Sizing of control valves, orifice plates, and relief valves

- Preparation of requisition and specifications for instruments

- Preparation of bill of materials

- Preparation of interface drawings for DCS, PLC, SCADA and MCC

- Preparation of earthing layouts for system and field

- Preparation of scope of work for construction activities

- Preparation of FAT and SAT procedures

- Preparation of as -built drawings and documentation

- Our engineers have expertise in related activities such as review of design criteria, review of contractor design documents and drawings , and project coordination.

- They are experienced in the use of a variety of supporting software including Smart Plant Instrumentation (INtools) andAutoCAD.

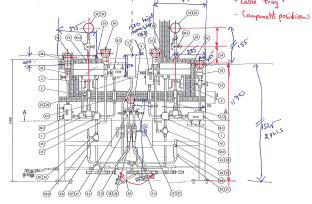

As-Built Engineering

Parc Tech has extensive experience with large as-built projects,

updating engineering records to match conditions in the field.

Our staff is skilled in traditional techniques such as manual

survey and redlining, as well as the latest technology such as laser scanning.

Parc tech as-built services include:

- As-built engineering from cloud point data

- Site survey and redlining

- Updating drawings as per red line markups

- Creation of intelligent P&IDs

- TEF integration

- 2D drawing conversion

Software Skill Sets & Standards

Process Simulation

- Hysys, HTRIand Pipe Net

Mechanical

- PVELITE

Civil & Structural

- STAADPro, SACS and TEKLA

Electrical

- ETAP and SPEL

Pipe Stress Analysis

- CAESAR II

Instrumentation

- SPI/INTOOLS

Piping

- PDMS, SP 3D, CADWorX, AutoPLANT, Inventor, Solidworks & BIM

Drafting

- AutoCAD & Microstation

Standards We Follow

- API, ASME, TEMA, BS, NFPA, AWWA, SHELL, DNV, NORSOK, ABS

- ASTM, DIN, JIS, ANSI

- IEC, IEEE, ISA

contact us

-

Parc Technologies Pte Ltd

- Address : No 1 Sophia Road, #04-26, Peace Centre,

Singapore 228 149 - Tel :+65-68111307, Fax :+65-68111310

- E-mail : sales@parctec.com

-

Parc Technologies Pvt Ltd

- Address : No 26-F2, Thiruvalluvar Street,Adambakkam,

Chennai, India 600 088 - Tel :+91-44 42033460, , Fax :+91-44 42033480

- E-mail : sales@parctec.com

-

PT. Parc Technologies Batam

- Address : Jl. Pelabuhan Sagulung KM 1 Tanjung Uncang,

Batam, Indonesia 29439 - Tel :+62-778-392 871, Fax:+65-68111310

- E-mail : sales@parctec.com

-

Parc Technologies Co., Ltd

- Address : No.99 Longhua Road, Yubei Discrict,

Chongqing, 401120 China - Tel :+86-23-67964368, Fax:+86-23-67504207

- E-mail : sales@parctec.com